Coated vs Uncoated Thermal Labels: Which Should I Choose?

Date Posted:1 October 2020

There are plenty of choices when it comes to ordering thermal labels: between direct thermal labels and thermal transfer, various sizes and label stock options. A lot of this will depend on your application, but there’s one decision we can help to clarify right now. We’re talking about the choice between coated and uncoated (eco) thermal labels.

.jpg)  |

Benefits of Coated Labels

While we’ve manufactured uncoated and coated labels in the past here at Thermal Labels, these days we choose only to supply top coated labels for a number of reasons.

Better label quality and longevity

Coated thermal label stock is generally more resistant to scratches and scuffs, light, moisture and other environmental issues than an uncoated stock. We’ve had many customers tell us they prefer the quality and longevity they get with a coated label, thanks to the extra protection.

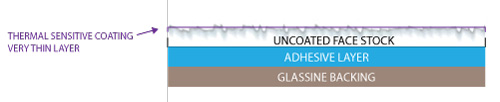

This is true of direct thermal shipping labels as well as thermal transfer labels. In a coated direct thermal label, a thin additional top coating sits over the thermal reactive layer and protects it against UV light, moisture and heat. Ultimately your direct thermal roll labels will stay scannable for longer, and the image will be crisper and clearer to boot.

Better lifetime costs of printers and printer parts

It’s generally expected that uncoated labels are cheaper to buy, but you really need to factor in the total lifetime costs of your label printing system to assess true value.

Uncoated label stock has a rough, uneven surface. Meanwhile the smooth surface on coated labels means less abrasion and therefore less wear and tear on your thermal printhead – particularly when you’re printing in high volumes. And when a new printhead can cost in the vicinity of $700-800 for a commercial barcode printer, it’s easy to see how investing a few extra cents on labels now can save you substantially over time. This is why it’s wise to look for quality over cost when it comes to labels.

Better printing efficiency

That smooth surface on a coated label gives you another advantage: printing speed. Coated labels can generally be printed at higher speeds than uncoated stock, which can really have an impact when you’re printing dozens, hundreds or even thousands of labels per day.

What about the environmental impact?

It’s a common assumption that uncoated labels are the more environmental choice between the two, but this is not necessarily the case. Uncoated and coated labels could both have high carbon footprints if the manufacturer doesn’t prioritise sustainability, so it’s worth checking with your label manufacturer about how they’re minimising their impact. Here at Thermal Labels we source a variety of Forest Stewardship Council (FSC)-certified label stocks, and are constantly looking for ways to optimise our energy efficiency, recycle and minimise landfill waste.

Read Related Article: From Deep Freeze to Full Sun: How Does Temperature Affect Thermal Labels?

If you are looking for thermal transfer or direct thermal labels and systems, including thermal labels for Zebra printers, then Thermal Labels is your one-stop shop. We’re a Sydney-based label manufacturer offering fast dispatch and delivery around Australia, and with close to 30 years in the business we’re happy to provide expert advice to keep you printing clearly.

Leave a comment